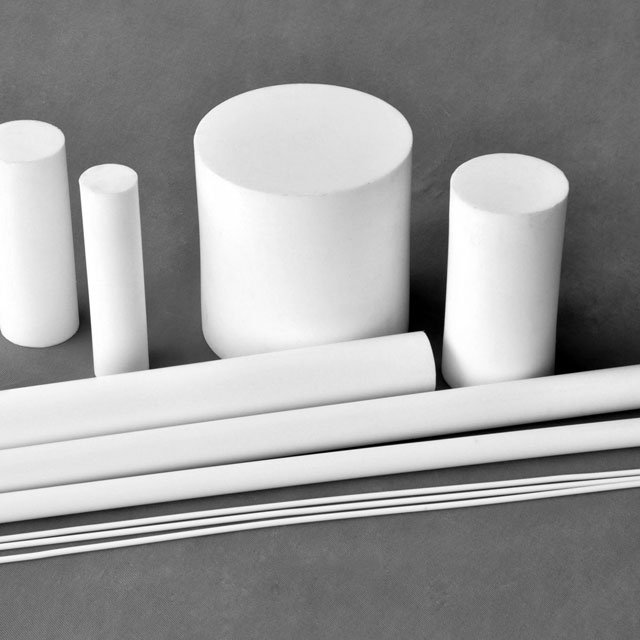

PTFE Teflon Rod

PTFE rods are made from polytetrafluoroethylene (PTFE), a versatile material widely used in various industrial applications. The applications include the gas and oil industry, automotive sector, medical treatment, and chemical processing, among others.

- Electrical insulation properties

- Highly Chemical resistant

- Low coefficient of friction

- PTFE is one of the most thermally stable plastic materials

PTFE Rods By Process

PTFE Molding Rod

Molded PTFE rods are made from molding PTFE powder.

Process: Molding Compression

Features:

Diameter 25mm-1000mm

Length:100m-300mm

Application: seals, gaskets, valve seats, and mechanical parts.

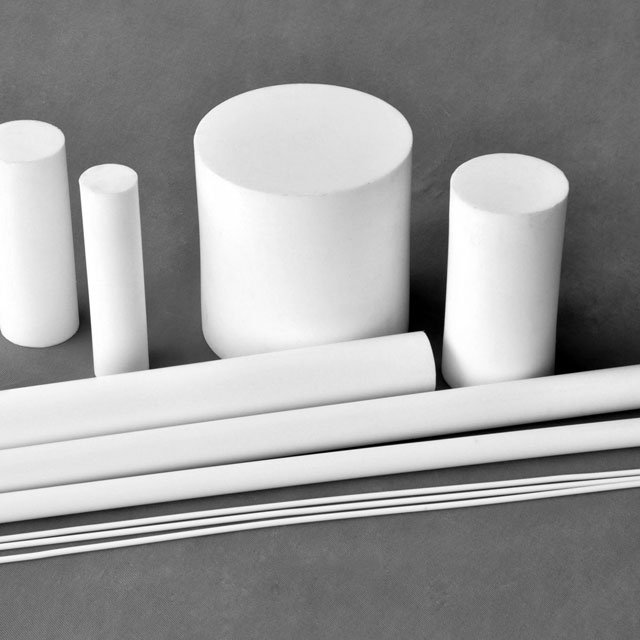

Virgin PTFE Rod

Materials: 100% pure PTFE, without any fillers.

Features: Excellent chemical resistance, high-temperature resistance, low coefficient of friction, and good electrical insulation.

Applications: Commonly used in the food, medical, electronics, and chemical industries for scenarios requiring high purity and corrosion resistance.

Teflon Rod Bunnings By Material

Virgin PTFE Rod

Materials: 100% pure PTFE, without any fillers.

Features: Excellent chemical resistance, high-temperature resistance, low coefficient of friction, and good electrical insulation.

Applications: Commonly used in the food, medical, electronics, and chemical industries for scenarios requiring high purity and corrosion resistance.

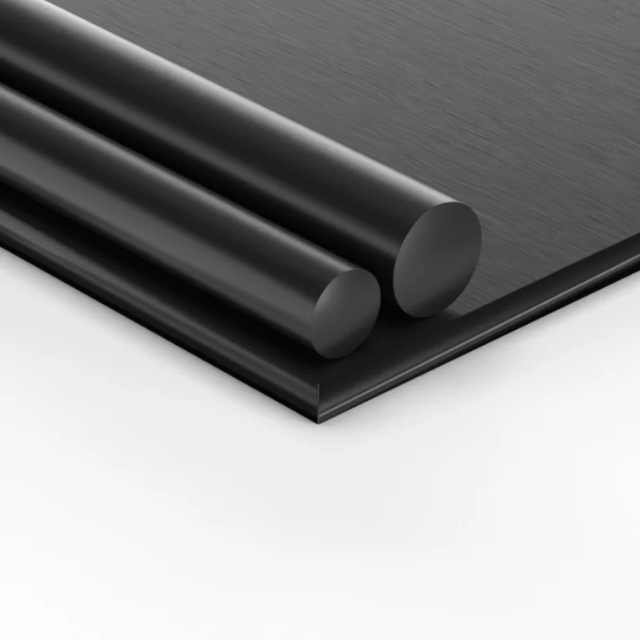

Carbon-Filled PTFE Rod

Materials: 15-25% carbon fiber.

Feature: Improved electrical conductivity and abrasion resistance.

Applications: Widely used in bearings, sliding parts and applications requiring high strength and heat resistance.

Glass Filled PTFE Rod

Materials: 5-40% fiberglass.

Features: Increased mechanical strength and wear resistance.

Applications: Used in seals, gaskets, and bearings for high load and high temperature applications.

Bronze Filled PTFE Rod

Materials: 40-60% bronze.

Feature: Increases mechanical strength, hardness, and thermal conductivity.

Applications: Suitable for plain bearings, valve seats, and high friction, high-temperature applications.

Graphite-Filled PTFE Rod

Materials: 5-15% graphite.

Features: Enhanced thermal conductivity and anti-static properties.

Applications: Suitable for valve seats, piston rings, bearings, and other parts requiring low friction and self-lubrication.

PTFE Rod Applications

PTFE Rods are used in many applications due to their excellent chemical stability, high and low temperature resistance, low coefficient of friction, and electrical insulation properties.

Reviews

About Customer reviews

We have been purchasing PTFE Rod for a long time, which is used to produce seals for chemical equipment. It has excellent corrosion resistance and remains stable even in strong acid and alkali environments, greatly enhancing the service life of the equipment.

Manager, WeServe LLC.

The low friction characteristics of PTFE Rod allow our guideway slides to run smoother and reduce the use of lubricants. This not only increases productivity, but also reduces maintenance costs.

Produce Manager

Contact Us

Whether you’re interested in our products, need a quote, or have any other requirements, we look forward to hearing from you. And you will get a perfact solution.

- Changqian Road, Kecheng, Quzhou,Zhejiang, China

- +86 13957007557

- info@peflon.com